PCB Depaneling with Different Cutting Fixtures Operated in

Y-direction

The depaneling process of this model is operated only in

Y-direction. Can be equipped with differing cutting fixtures. It

should be noted here, that the PCB panel is processed in Routing

Spindle.

The routing spindle is mounted onto a Y- linear-axis system which

cuts the panel in the Y-direction. The stopper will allows

automatic processing of different sized PCBs.

Specification:

| I. Hardware | |

| SPINDLE | KAVO spindle(Model:4051) |

| CCD | Sony 520 line industrial cameras |

| LENS | Computar EX2C |

| Screw | TBI Precision ground ball screw imports |

| Guide | HIWIN widening Imported linear guide rail |

| MOTOR | JiaBao LCF Series |

| I/O CONTRONL CARD | HFC PCI-9074 |

| DRIVER CONTRONL CARD | HFC PCI-9074 |

| I/O CARD | PCI-9074-64pcs/-38pcs |

| Static cleanup | STATIC-ST401A Series |

| Computer | (RMC-8401/6113LP4/300ATX/8651VNA/P4 2.8G 2CPU(S)/1G DDR/80G) |

| Machine interface | AOC LCD17",Logitech mouse |

| 2. software | |

| Control system | Windows XP Professional (Service3,v.3244) |

| Operation GUI | English Windows XP |

| Program edit | Inline |

| Vision system | CCD AOTU offset |

| Control system | F 1.2.88 version |

| Overall | |

| Dimensions(W*D*H) | 1280mm*1450mm*1480mm |

| Weight | 750KG |

| Height offset | 60~110mm |

| Manipulator | |

| Motor type | JiaBao series |

| Positioning repeatability | 0.001mm |

| Axis working area(max) | 890mm*560mm*50mm |

| Work station | |

| PCB fixation | standard,specialization |

| PCB loading/unloading | manual |

| PCB size (max) | 450*350mm |

| PCB thick (max) | 5mm |

| Fixturing | |

| Rigidity fixturing | Customized make fixture |

| Fixturing fixation | machinery |

| Spindle Motor | |

| Power | 150W |

| Spindle | 60000rpm/min |

| Protect | self/wind cooling |

| Change cutter | Specialization |

| Routing capability | |

| Cutting speed(max.) | 80mm/s |

| Driving speed(max.) | 2500mm/s |

| Precision of cutting | 0.01mm |

| Vacuum System | |

| Vacuum power | 3.5KW AC 380V |

| Vacuum | plumb |

| Utilities | |

| Power | 2.0KW AC380V |

| Air supply | 4-6KG/cm2 |

| Programming | |

| Program edit | Inline |

| Function edit | Line,arc,circula,U-curve |

| Program storage | HDD |

| Vision system | SONE colour CCD |

| milling cutter offset | AUTO |

| Vacuum setup | AUTO |

| Operation Monitors | |

| Iindicator | Iindicator Machine state |

| tool check | Automatic detection tool life, the use of time testing |

| Motor protect | Have overheating, overload, low voltage protection function |

| motor over loading check | Have Overload, the line is normal, low voltage protection function |

| Tool usable time | Automatic detection tool life, |

| Data statistic | Separate board model, separating count, diverse counting methods |

| Error record | Software automatically records all alarms memory of machines |

| III. Accuracy | |

| Axis precision | 0.001mm |

| Cutting precision | 0.1mm |

| IV. Safety | |

| Working area protect | With four sealed protection |

| Door sensor | Front and rear safety door micro-switch sensor (optional) |

| Exigency stop button | |

Features:

1. Twin working table are alternately cutting, it is possible

loading and takeoff PCB work during another table cutting.

2. Special cutting result that low-stress, hi-accuracy, hi-quality

with router bit

3. Alternately-cut different program

4. User friendly drastically improved display function by use of

touch panel

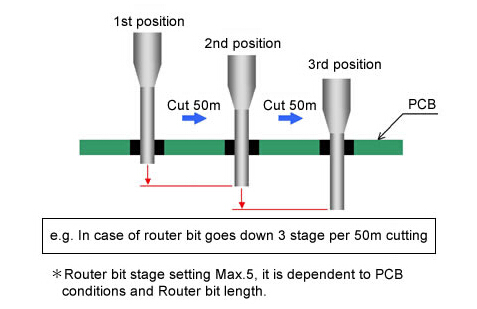

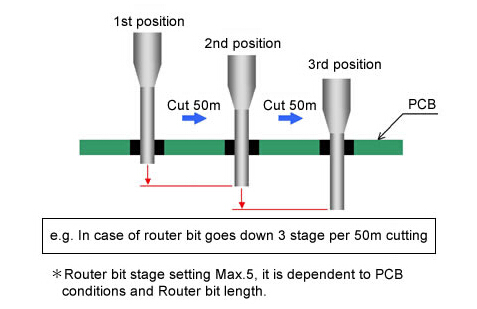

5. Reduced running cost with the function of Z axis height

multistage-auto-changeover by router bit life(count cutting sheet

or distance) management

6. It correspond with large size PCB(550mmx450mm by changing for

large main base)

7. Prevent product failure by detection of router bit drops and

broken

8. Easily create cutting program even there is no PCB CAD data with

the use of TEACHING CAMERA(Option)

Packaging Photos:

More information welcome to contact us:

Email:s5@smtfly.com