I. Description

Durostone is a heavy-duty glass fiber reinforced plastic which

offers extreme strength and excellent electrical, thermal and

chemical properties. It can keep its mechanical strength,

smoothness and original color when continuously used under the

temperature of 280°C (max. working temperature below 385 degree 10~20sec).

In addition, durostone have the advantage of easily machining, high

intensity and can be easily machining into special mechanical

parts.

II. Main Characteristic

1. Normal working temperature at 325 °C, operating temperature up

to 384 °C

2. Less distortion, low thermal conductivity

3. Superior dimensional stability, Long life

4. High temperature resistance

5. Resistance to chemical corrosion

6. High mechanical strength

7. Good machinability (low density)

III. Application

Functions:

1. Support thin baseboard or soft substrate circuit board

2. Carry an irregular shape solder pallet

3. Use multi-pak panel design to improve production efficiency

4. Prevent the deformation of the solder pallet during high

temperature reflow soldering process

5. Smoothly surface, good endurance, applicable for Teflon spray

painting

6. Avoid gold finger contamination by human contact

7. Protect bottom side SMT components during the wave soldering

process

8. Prevent the deformation of the baseboard during the wave

soldering process

9. Standardized the width of the production lines, eliminate the

width adjustment of the production line

10. Prevent baseboard being contaminated by the overflow of tin

Benefits

1. Wave Solder Pallets provide strong, stable support for the PCB

throughout the wave solder process

2. Wave Solder Pallets permit wave solder processing of

through-hole components while masking solder-side SMT components

and critical board features from molten solder

3. Wave Solder Pallets provide thermal protection for printed

circuit board areas that are heat sensitive

4. Wave Solder Pallets allow processing of odd-shaped PCB's through

conveyor system

5. Wave Solder Pallets prevent topside component movement

throughout wave solder

6. Wave Solder Pallets align and position topside components

throughout wave solder

7. Wave Solder Pallets increase assembly production by eliminating

hand gluing and masking operations

8. Wave Solder Pallets ensure higher quality, repeatable process

results

9. Wave Solder Pallets reduce bridging and skipping solder defects

10. Wave Solder Pallets provide safe, easy, ergonomic handling of

PCB

Specification:

| Model | DurostoneCHP760 | DurostoneCAS761 | DurostoneCAG762 |

| Grade | Standard | Anti-Static | Anti-static(Optical) |

| Colour | Blue | Black | Grey |

| Density(g/mm3) | 1.85 | 1.85 | 1.85 |

| Standard OperationTemperature | 260 | 260 | 260 |

| Maximum Operation Temperature(C) | 350 | 350 | 350 |

| Sheet Size(mm) | 2440×1220 | 2440×1220 | 2440×1220 |

| Tickness/weight(mm/kg) | 3/17, 4/22 | 5/28, 6/33, 8/44 | 10/55, 12/66 |

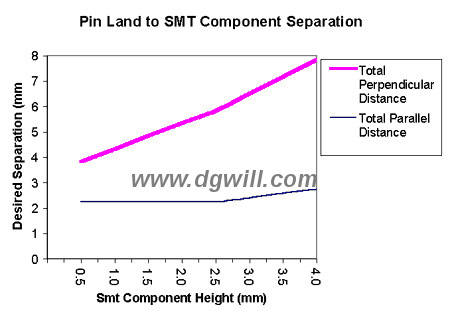

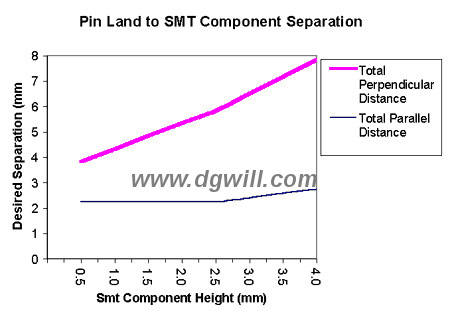

Working your way around the underside of the PCB, identify which

components

are parallel and perpendicular to the wave and assess the

solderability of each

PTH connector by comparing the actual separation against the graph

right.

Ideally you want to be above the line in all cases.

CE approval