Wave Solder Pallet Compatibility 2440×1220 Suitable for High

Temperature

Specification:

| Model | DurostoneCHP760 | DurostoneCAS761 | DurostoneCAG762 |

| Grade | Standard | Anti-Static | Anti-static(Optical) |

| Colour | Blue | Black | Grey |

| Density(g/mm3) | 1.85 | 1.85 | 1.85 |

| Standard OperationTemperature | 260 | 260 | 260 |

| Maximum Operation Temperature(C) | 350 | 350 | 350 |

| Sheet Size(mm) | 2440×1220 | 2440×1220 | 2440×1220 |

| Tickness/weight(mm/kg) | 3/17, 4/22 | 5/28, 6/33, 8/44 | 10/55, 12/66

|

Feature

1. Used materials imported synthetic stone materials, quality

imported bakelite, glass fiber, alloy

2. Reflow soldering printed circuit board tooling

3. Decrease deformation of the substrate caused by the tin stove

and electrostatic breakdown

4. Applicable substrate shape

5. Loading multiple PCB production line, saving manpower and after

welding, improve productivity

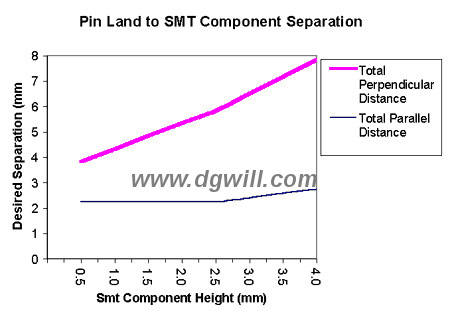

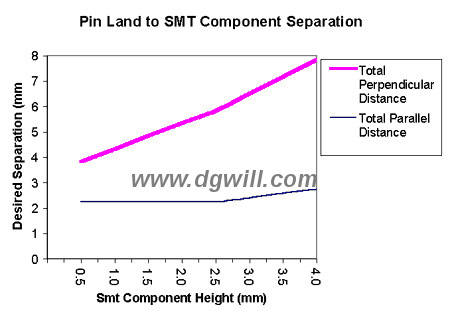

PTH Components Located Perpendicular to direction through wave.

A larger separation is required due to the solder having to flow

"under"

component pockets.

Working your way around the underside of the PCB, identify which

components

are parallel and perpendicular to the wave and assess the

solderability of each

PTH connector by comparing the actual separation against the graph

right.

Ideally you want to be above the line in all cases.

PCB Design Implications - for Board Designers - or respin

We are often called upon by our customers to help with identifying

design respin opportunities.

We will identify problem areas within a board and suggest

appropriate movements of components. (Ideally before the PCB is

fabricated)

However for board designers reading this, can you remember another

four "rules" (to compete with the hundred other rules you have to

have floating

around in your head).

Keep large (height) SMT components away from PTH areas.

Leave the leading and trailing areas around PTH components as clear

as possible.

DON'T put any SMT components within 3mm (0.12") of any PTH

components.

DON'T put all PTH components in line along one edge of a board -

leave some space to allow us to support the masking in the centre

of the board.

We recommend to use Reflow Pallets of Durostone Material, for your

different PCB shapes, thin PCB material use to avoid warpages on

your assembled board. You will be able to work effective with every

kind of shapes and material thicknesses.

The following are the general data files required for fixture

development. Products are processed differently. Supplying us with

all of this data will ensure that we have what is needed for your

application.

Top & Bottom Side Silkscreen

Top & Bottom Side Paste

Top & Bottom Side Mask

Fabrication Drawing

Drill Fab Layer

Other Requirements:

Height of components on the solder side of the PCB

Height of components requiring hold downs

Identify any components which overhang the board and whether they

seat flush to the top of the PCB or receed to a certain depth

FAQ

(1) Discount price yes&no ?

It is depending on the volume. The larger the volume is, the more

discount you can

enjoy.

(2) Why your price is a bit higher than other Chinese suppliers?

To meet the requirement of different customers and areas, our

factory manufactures

various kinds of quality for each item at a wide range of price. We

can offer the

products of different quality levels depending on customer’s target

price and quality

requirement.

(3) If I can get a sample ?

For existing samples (sizes not larger than 300*300mm) can be sent

free of charge

but you just need to bear shipping charge, or you can provide your

DHL, FEDEX,

EMS, UPS courier account number to us.

For bigger sizes, or customized samples, it depends on negotiation.

(4) If you can guarantee the quality of mass production is same

as the sample sent to me before?

Quality is our culture, is our life. We believe our products will

give you a surprise.

Our warehouse staff will leave another same sample in our

workhouse, and marked

your company name on it, which our production will be based on.

(5) How can you deal with quality issues after receiving the goods?

1) First you take photos of unqualified goods and then our sales

staff will send

them to Manufacturing Department to verify.

2) If the problem is confirmed, our sales will explain the root

cause and take

corrective actions in coming orders.

3) Finally, we will negotiate with you to make some compensation.

Production flow