Durable PCB Solder Pallets SMT Trays for Selective Wave Soldering

Used by most of our customers because of some advantages:

1. Faster positioning on production line

2. Low costs due to the missing of reinforced bars

3. Better volume stocking

4. Better yield with different board type on the production line

Surface-mount technology (SMT) is the leading factor driving higher

circuit densities per square inch on PCBs. Directly attaching

components and devices to the surface of circuit boards has enabled

products to perform with much higher circuit speeds, allowed

greater circuit density, and requires fewer external connections.

These advances have greatly lowered costs, improved performance and

product reliability. However, these benefits do not come without

their challenges. Printing solder paste on diminishing pad sizes,

placing smaller components, and reflowing entire assemblies with

their varieties of termination finishes and materials are just a

few of the technical challenges that process engineers face every

day.

ADJUSTABLE SCREEN PRINT PICK-N-PLACE REFLOW PALLET

Adaptable for the Smaller PCBs designed to go through the entire

SMT line, and will adapt for non-rectangular PCBs as well

Uses edge tension to secure the board in place

Fiducial orientation mark located on corner of pallet

Each pallet has rail steps on all four sides

Pallet centers the PCB and offers recognized placement of one

corner for multiple pallets to maintain alignment

360-degree Fixture

This fixture allows for 360-degree rotation adjustments for

optimized angle to receive the solder wave application.

This option provides the best results for minimizing bridging and

opens.

45-degree Fixture

This 45-degree fixture allows 80 degrees of rotation adjustment

with a lower cost adjustable as compared to the above 360-degree

fixture.

This option provides the best results for minimizing bridging

between pins.

Specification:

| Model | DurostoneCHP760 | DurostoneCAS761 | DurostoneCAG762 |

| Grade | Standard | Anti-Static | Anti-static(Optical) |

| Colour | Blue | Black | Grey |

| Density(g/mm3) | 1.85 | 1.85 | 1.85 |

| Standard OperationTemperature | 260 | 260 | 260 |

| Maximum Operation Temperature(C) | 350 | 350 | 350 |

| Sheet Size(mm) | 2440×1220 | 2440×1220 | 2440×1220 |

| Tickness/weight(mm/kg) | 3/17, 4/22 | 5/28, 6/33, 8/44 | 10/55, 12/66 |

Our sales network

This estimation may be done in three ways

If a PCB is available (preferably populated) - our sales engineers

can rapidly evaluate your board.

If PCB design data is available we will process, analyse and

remotely assess it.

You can do it using the rules presented below - our customers

quickly find that the above two methods are easiest.

Gerber, Excellon and other data required

Pin Land to SMT pad clearance evaluation

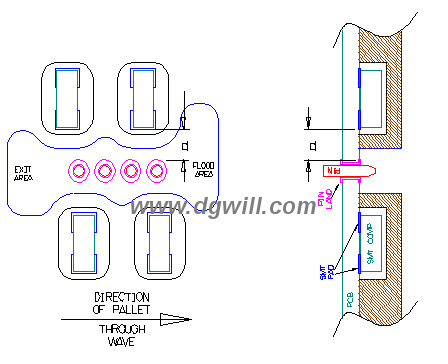

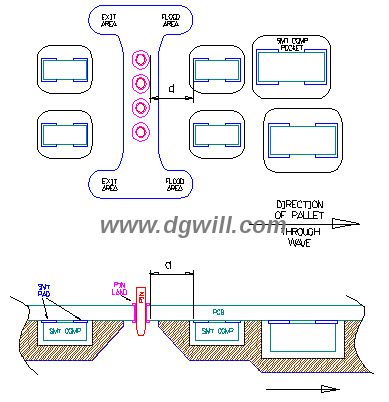

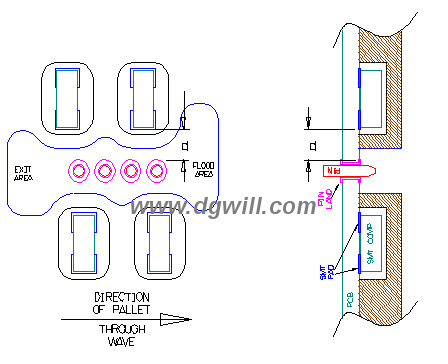

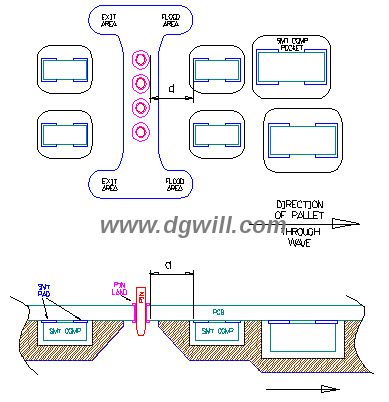

The two figures below each show part of a CSWSC in plan and section

views. The right hand figure shows that more clearance

is required when the connector orientation is perpendicular to the

wave.

PTH Components Located Parallel to direction through wave

The clearance required between the pin land and SMT pad can be made

quite

small, as the solder does not have to flow "under" the component

pockets.

PCB Design Implications - for Board Designers - or respin

We are often called upon by our customers to help with identifying

design respin opportunities.

We will identify problem areas within a board and suggest

appropriate movements of components. (Ideally before the PCB is

fabricated)

However for board designers reading this, can you remember another

four "rules" (to compete with the hundred other rules you have to

have floating

around in your head).

Keep large (height) SMT components away from PTH areas.

Leave the leading and trailing areas around PTH components as clear

as possible.

DON'T put any SMT components within 3mm (0.12") of any PTH

components.

DON'T put all PTH components in line along one edge of a board -

leave some space to allow us to support the masking in the centre

of the board.