Technical parameters:

1 Power supply: AC220V ± 10%, 50Hz, 3500W

2 Work environment :10-60 ℃, 40% ~ 95%

3 Working pressure: 0.5 ~ 0.7Mpa

4 Welding pressure: 2.5 ~ 28Kgf

5 Temperature settings: three sections (including start /

separation)

6 Temperature settings: RT ~ 450 ℃

7 Pressing time: 1 ~ 99 s

8 Hot Accuracy: pitch 0.14mm

9 Production capacity: 220pcs / h

10 Hot Head size: MAX 50 × 8mm

11 Dimensions: approx (L) 500mm × (W) 700mm × (H) 810mm

12 Weight: about 120KG

Thermode Specifications

Maximum Thermode Area 400 mm²

Maximum Thermode Length 100 mm (normal)

Force Range 30 N @ 0.09 MPa to 600 N @ 0.6 MPa

Thermode Stroke 50 mm

Force Accuracy ±

Actuation Type Pneumatic

Pulsed Heat Control Specifications

Temperature Range 1° C Interval

Idle 0 to 150° C

Preheat 0 to 500° C

Reflow 0 to 500° C

Time Periods 1 Second Interval

Preheat 0 to 200 Seconds

Reflow 0 to 200 Seconds

Heating Rate Control Eight (8) Selections

Programmable Heat Profiles Four (4) Internal Memory

Thermode Cooling Air For Cooling Thermode

SmarTherm HSM

Compressed Air: 4 to 6 Bar

Vacuum Flow Rate: 24L/min Maximum

Electrical Power: 220 or 110 Vac (Factory Preset)

Weight: Net - 91Kg, Gross 159Kg

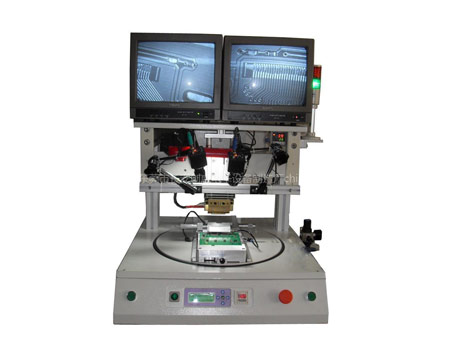

Features:

1. PLC control system, pulse heating, hot head with titanium to

achieve rapid warming. Rapid cooling, temperature control and

accurate.

2. Duplex rotation rotation feeding, enhance efficiency.

3. The on-bit dual camera system.

4. Optional touch screen control functions.

Uses: Suitable for all kinds of ordinary TAB, TCP crimping, and

FPC, FFC and PCB solder crimp.