Reflow Wave Solder Pallets Matrix Fixture Adjust PCB Fixtures

FLEX CIRCUITS ARE A SPECIALTY AT CW

The demand for CW’s SMT Assembly Fixtures is growing as they are a

solution to solving many of the challenges associated with SMT

assembly. Our solid design capabilities are proven to handle even

thin PCBs as well as brands with unusual form factors. Some of

DMI’s design features include:

1. Optical grade composites to make it much easier for the PCB

present sensors to ‘see’ the fixture.

2. CW offers a unique design using a built-in spring-tension pin to

hold the PCB in place for ultra-precise applications or

interference fits. These sliding board tension locks secure PCB’s

(ranging in thickness from 0.005” to 0.125”).

3. CWs pallets are designed to set the PCB .005” ‘proud’ above the

fixture for optimal screen printing results.

IMPROVE YIELDS BY ENSURING CRUCIAL BOARD PLANARITY AND SOLID

ALIGNMENT ACCURACY DURING THE REFLOW PROCESS.

Print through & reflow pallets keep the PCB flat providing solid

stabilization for the stencil during the reflow process. DMI

developed a special pin for the purpose of holding

evenly-distributed tension on the PCB.

This innovative technique allows the operator to maintain both the

crucial planarity of the PCB and the critical alignment of the

stencil during the process of printing solder paste, component

pick-n-place, and the soldering of components.

CW’s implementation of this innovative pin design has eliminated

the need for Kapton tape, reducing materials waste and offering a

cleaner securing and releasing of the PCB from the pallet. This

quick and easy method is far less labor intensive and more

economical.

Because no tooling parts extend more than a few thousands of an

inch above the surface of the PCB, CW’s print through & reflow

pallets work exceptionally well for the stencil to print properly

on even thin PCBs with thicknesses under 0.010”.

FIDUCIALS FOR ALIGNMENT OF THIN PCBS (LESS THAN 0.040”)

For PCBs that can offer challenges during reflow operations, we

offer fiducials on the pallet to align the PCB to both the stencil

printer and pick-n-place machine.

Because the pallets hold the PCB flat, crucial planarity is

constantly maintained. This helps ensure accuracy throughout the

stencil paste application process and the component pick-n-place

process, ultimately improving yields.

TENSION PINS FOR THIN PCBS (LESS THAN 0.040”)

On flex PCBs, DMI offers tension fitting to provide secure and

accurate seating of PCBs against pallets. By using custom pins

mounted on spring leavers, PCB is stretched firmly into the recess

of the pallet to maintain proper orientation during stencil screen

printing and accurate pick-n-place. Fiducials are valuable on any

Print Through & Reflow pallet.

COMPRESSION FITTING FOR ALIGNMENT OF THICK PCBS (0.040” TO .240”)

On thicker PCBs,CW offers compression fitting to provide secure and

accurate seating of PCBs against pallets. By using edge tensioners,

the PCB is held firmly into the recess of the pallet to maintain

proper orientation during stencil screen printing and accurate

pick-n-place.

Specification:

| Model | DurostoneCHP760 | DurostoneCAS761 | DurostoneCAG762 |

| Grade | Standard | Anti-Static | Anti-static(Optical) |

| Colour | Blue | Black | Grey |

| Density(g/mm3) | 1.85 | 1.85 | 1.85 |

| Standard OperationTemperature | 260 | 260 | 260 |

| Maximum Operation Temperature(C) | 350 | 350 | 350 |

| Sheet Size(mm) | 2440×1220 | 2440×1220 | 2440×1220 |

| Tickness/weight(mm/kg) | 3/17, 4/22 | 5/28, 6/33, 8/44 | 10/55, 12/66 |

Our sales network

This estimation may be done in three ways

If a PCB is available (preferably populated) - our sales engineers

can rapidly evaluate your board.

If PCB design data is available we will process, analyse and

remotely assess it.

You can do it using the rules presented below - our customers

quickly find that the above two methods are easiest.

Gerber, Excellon and other data required

Pin Land to SMT pad clearance evaluation

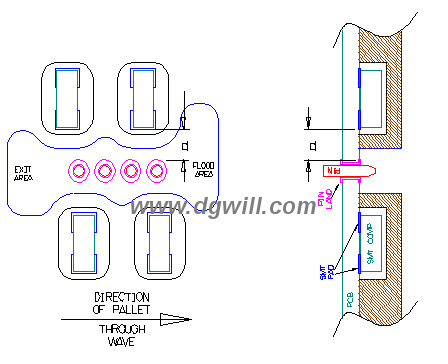

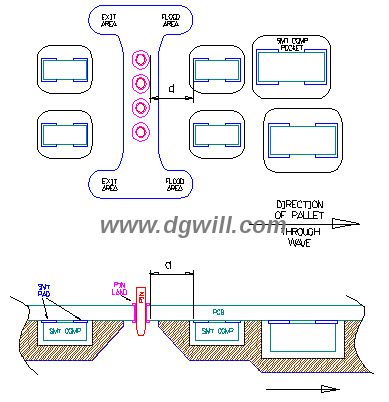

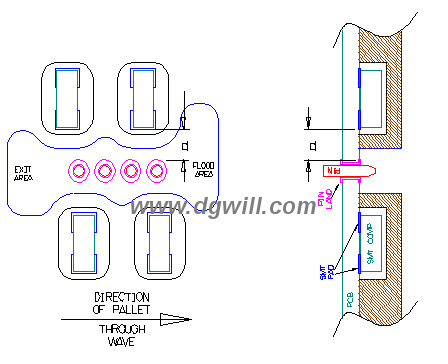

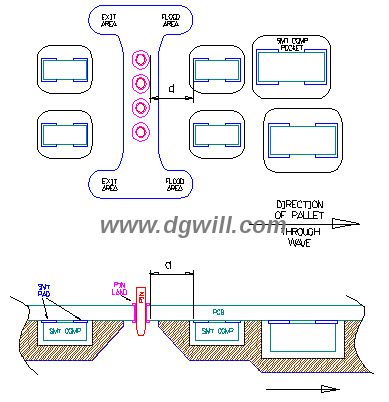

The two figures below each show part of a CSWSC in plan and section

views. The right hand figure shows that more clearance

is required when the connector orientation is perpendicular to the

wave.

PTH Components Located Parallel to direction through wave

The clearance required between the pin land and SMT pad can be made

quite

small, as the solder does not have to flow "under" the component

pockets.

PCB Design Implications - for Board Designers - or respin

We are often called upon by our customers to help with identifying

design respin opportunities.

We will identify problem areas within a board and suggest

appropriate movements of components. (Ideally before the PCB is

fabricated)

However for board designers reading this, can you remember another

four "rules" (to compete with the hundred other rules you have to

have floating

around in your head).

Keep large (height) SMT components away from PTH areas.

Leave the leading and trailing areas around PTH components as clear

as possible.

DON'T put any SMT components within 3mm (0.12") of any PTH

components.

DON'T put all PTH components in line along one edge of a board -

leave some space to allow us to support the masking in the centre

of the board.