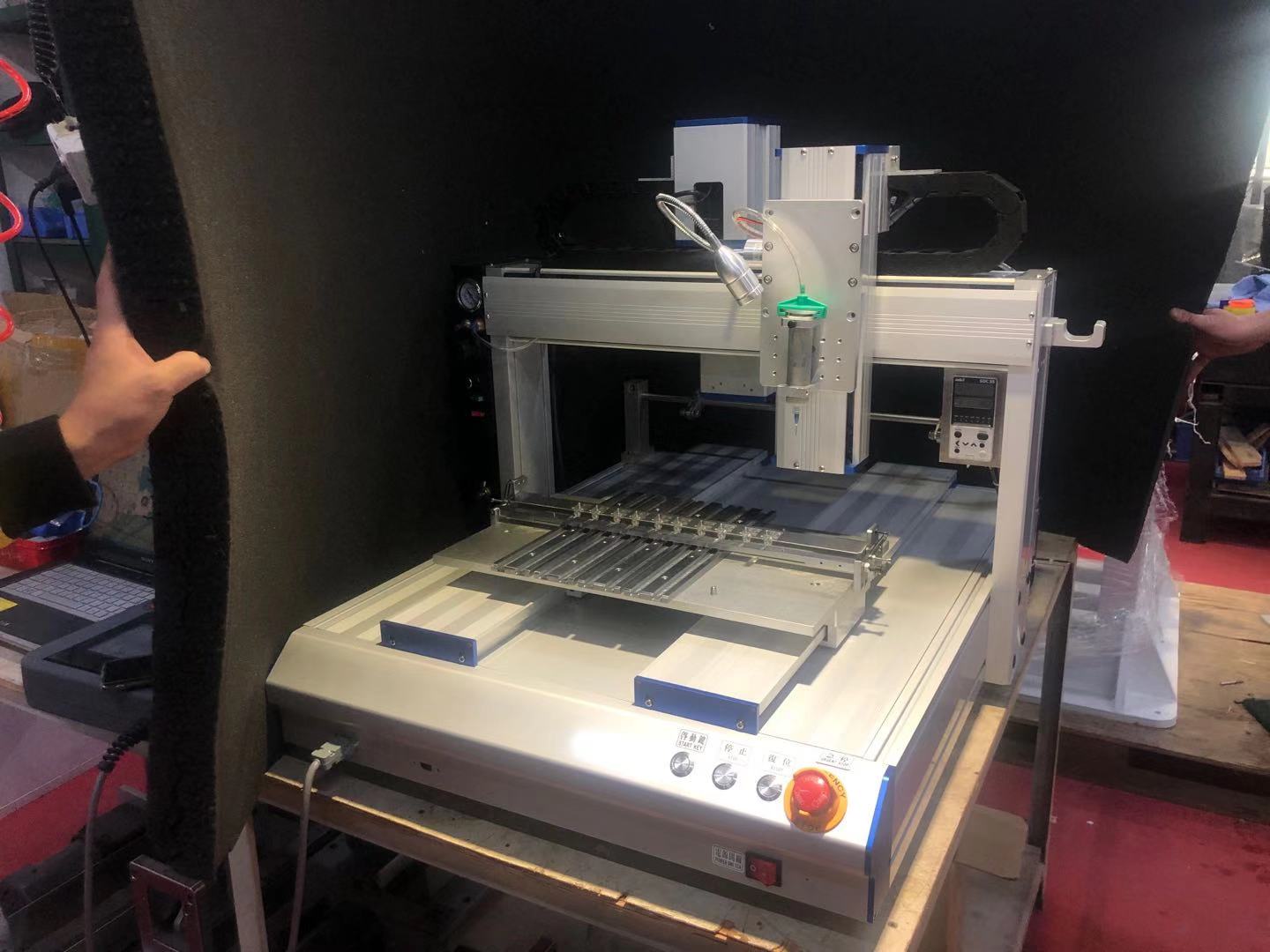

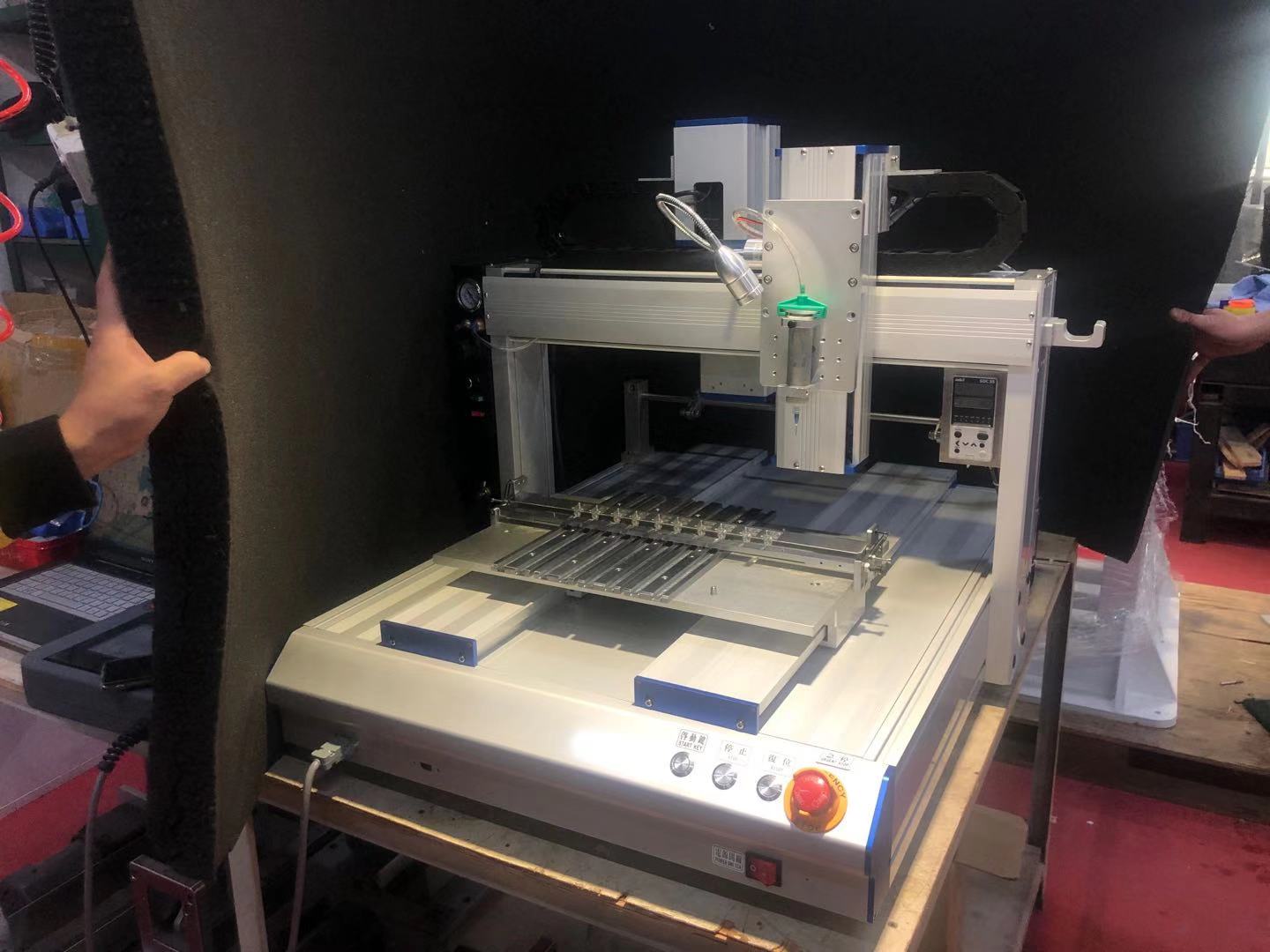

Soldering Maching for Soldering Flex PCB to PCBA Boards,Dispenser

Solder Paste to FPC then Soldering Feature:

Applicable to different products, adjustable heating rate;

Titanium alloy indenter ensures average temperature, fast heating

rate and long service life;

The indenter is horizontally adjustable to ensure that the

components are flattened;

Imported temperature controller, precise and stable;

Small size, using front and rear double station mode to improve

work efficiency;

Servo motor drive replaces traditional cylinder structure with high

precision and better stability.

Soldering Maching for Soldering Flex PCB to PCBA Boards,Dispenser

Solder Paste to FPC then Soldering Maintenance

1. The welding head is cleaned regularly every day.

2. Do not set the temperature higher to prevent soldering products

3. The welding head has a high working temperature for a long time,

pay attention to prevent burns.

4.X, Y, Z guide rails regularly add butter every quarter

5. When the machine is abnormal, press the emergency stop switch

until the abnormality is removed before starting the work normally.

Soldering Maching for Soldering Flex PCB to PCBA Boards,Dispenser

Solder Paste to FPC then Soldering Parameter:

| Item | Parameter |

| Working area(mm) | 300*300 |

| Working pressure(Mpa) | 0.4-0.7 |

| Fixture/Die(PCS) | 1 |

| Machine size(mm) | 820*900*700mm |

| Weight(Kg) | 140Kg |

| Max soldering area | 6*160 |

| Heating method | Pulse |

| Temp Setting(℃) | 0-500 |

| Temp error(℃) | ±2 |

| Soldering time(s) | 1-99 |

| Heating power(KW) | 3 |

| Soldering accuracy(mm) | ±0.02 |

| Heating setting | 2 line |

| Heating speed(℃/s) | 200 |

Soldering Maching for Soldering Flex PCB to PCBA Boards,Dispenser

Solder Paste to FPC then Soldering Package: